This technology allows for increased heat transfer to the reservoir and greater thermal efficiency, improving surface- and reservoir-level steam quality to increase reservoir productivity.

The SMH is a complete system, dedicated to generating and injecting high-quality steam into oil wells. It consists of an advanced technology that encourages additional oil production, reduces costs, and decreases operating time through a more sustainable, and thus profitable, process.

HOW DOES IT WORK?

These systems can operate with feedwater with high total dissolved solids (TDS) without losing water condensate or thermal energy in the saturated condensate. A steam quality of 95% makes steam injection efficient and very profitable in enhanced oil recovery (EOR) processes.

These systems consist of a high-efficiency cyclone steam separator; a tube assembly, superheater or superheater coil; mixers with automatic control valves; and a steam quality sampling system for continuous monitoring.

Nakasawa’s SMH and SMC processes involve controlled condensate separation and remixing with a sprinkler mixer, all operated by an automatic control valve to obtain a steam quality of at least 95%. This means there is no loss of condensate, and the total mass goes to the system outlet and injection point.

STAGES OF THE PROCESS:

A-B-C-D-1-2-3

The SMH or SMC follows a process similar to that of a conventional generator. In this stage, wet steam is generated (75% - 80%), with a radiant section (outlet).

E

The wet steam is separated into more than 99% dry steam and saturated condensate inside the high-efficiency cyclone separator.

F-4

The dry steam is superheated in a tube assembly or superheater.

G-5-6

Finally, because it is a continuous generation process, the superheated steam is once more mixed with the separated condensate to achieve the desired 95% dry steam at the system outlet. In this phase, controlled condensate remixes are performed to ensure there is no condensate lost or effluent generated; the total mass goes to the system outlet. It is important to highlight that no extra solids or incrustations are generated throughout the entire process.

G-H

In this phase, there is a controlled remixing of the condensate and dry steam, so there is no loss of condensate or effluent is generated and the total mass of water leaves the system as steam with 95% dryness.

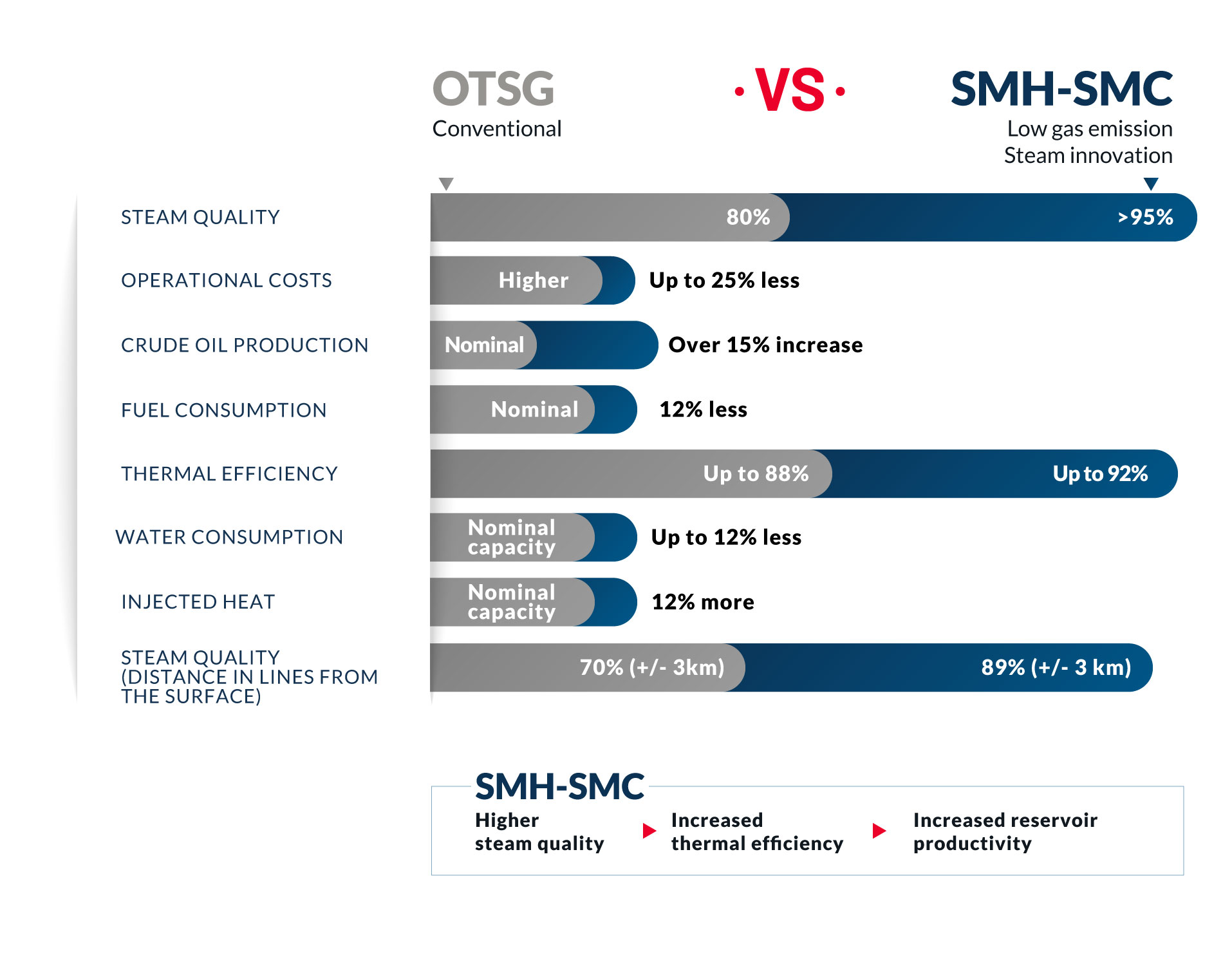

ADVANTAGES OF THE SMH AND SMC VS. CONVENTIONAL OTSG

SERVICE AND SUPPORT IN EVERY STEP

Nakasawa ensures that its clients’ projects are successful, building a technical alliance that starts with project strategic design and continues through to its implementation, maintenance, and monitoring.

Nakasawa provides full project implementation services, including the human resources and consumables needed to ensure successful enhanced oil recovery in new and mature heavy oil wells. In turn, clients can benefit from personnel trainings on the optimal use of SMH or SMC technology, ensuring they can handle the technology on their own and without any complications as their goals are achieved.

NAKASAWA RESOURCES

BY YOUR SIDE

Nakasawa’s complete service for implementing its steam injection technologies includes

- Reservoir analysis.

- Steam generator service and operation, including equipment and auxiliary services.

- Completion systems and equipment for injection wells.

- Completion systems and equipment for production wells.

- Monitoring of reservoir variables, optimization, and production.

GUIDELINES AND REGULATIONS

Steam injection services must comply with all applicable national and international regulations at all times, and shall only be provided after taking the equipment manufacturers’ recommendations regarding installation, wiring, calibration, testing, special requirements, and others into account. This will ensure the equipment’s proper functioning and operation. Among the regulations that govern this service are:

- ISA (International Society of Automation)

- IEC (International Electrotechnical Commissions)

- ANSI (American National Standards Institute)

- A.P.I. (American Petroleum Institute)

- ASME (American Society of Mechanical Engineers)

- NEMA (National Electrical Manufacturers Association)

- NFPA (National Fire Protection Association)

- ASTM (ASTM International)

- ISO (International Organization for Standardization)