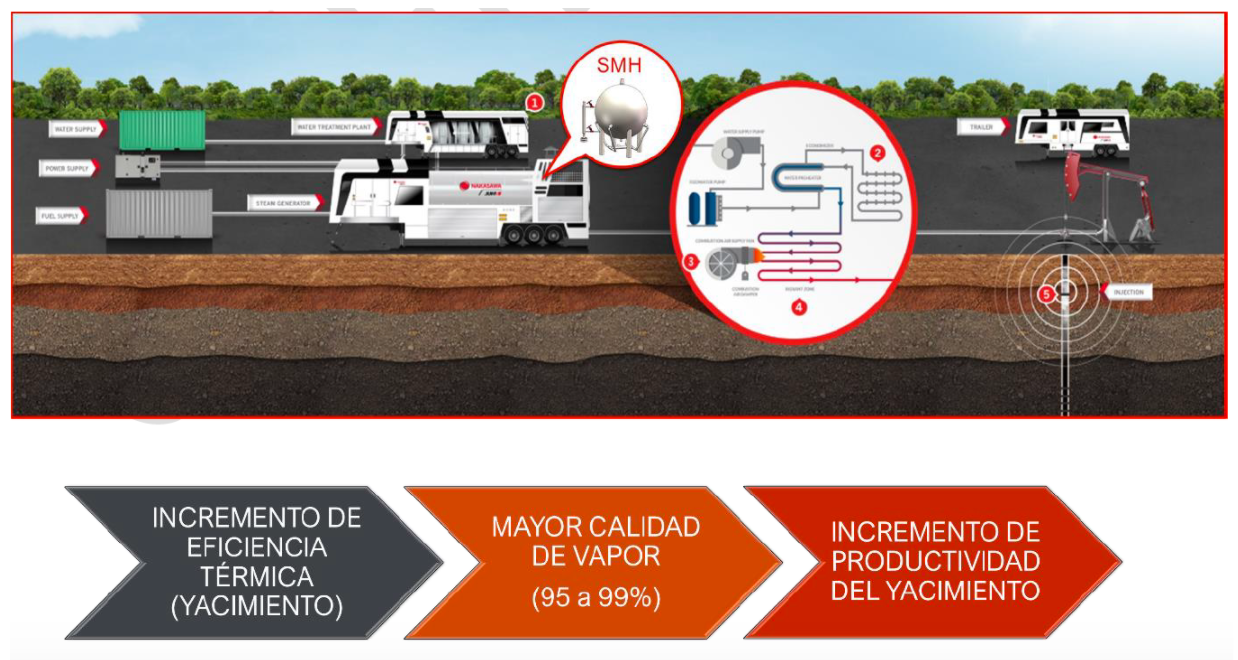

Esta tecnología permite incrementar la transferencia de calor al yacimiento teniendo mayor eficiencia térmica, mejorando la calidad de vapor en superficie y a nivel de yacimiento, e incrementando la productividad de los yacimientos.

Un sistema completo, dedicado a generar e inyectar alta calidad de vapor en pozos petroleros. Cuenta con una tecnología avanzada que incentiva la producción de más

petróleo; así como la disminución de gastos y tiempo de operación mediante un proceso más sostenible y rentable.

¿CÓMO LO HACE?

Estos sistemas pueden operar con agua de alimentación de altos sólidos disueltos totales (TDS) sin pérdida de agua condensada y energía térmica en el condensado saturado. El vapor con un 95% de calidad hace que la inyección de vapor sea efectiva y muy rentable en procesos de recuperación mejorada de hidrocarburos (EOR).

Los sistemas constan de un separador de vapor ciclónico de alta eficiencia, un conjunto de tubos, sobrecalentador o bobina supercalentadora, mezcladores con válvula de control automática y un sistema de muestreo de calidad de vapor para monitoreo continuo.

Los procesos del SMH y SMC de Nakasawa implican separaciones y remezclas controladas del condensado con un sprinkler mixer operado por una válvula de control automática para obtener calidades de vapor desde 95%; por lo tanto, no hay pérdida de condensado, y la masa total va a la salida del sistema y punto de inyección.

FASES DEL PROCESO

A-B-C-D-1-2-3

Se sigue un proceso similar a un generador convencional. En esta etapa se logra la generación de vapor húmedo (75% - 80%), sección radiante (outlet).

E-4

Luego el vapor húmedo se separa en más de 99% de vapor seco y condensado saturado dentro del separador ciclónico de alta eficiencia.

F-5

El vapor seco se sobrecalienta en un conjunto de tubos o sobrecalentador.

G-H-6

Por último, por tratarse de un proceso de generación continua, el vapor sobrecalentado se vuelve a mezclar nuevamente con el condensado separado para lograr la sequedad de vapor deseada del 95% en la salida del sistema. Las corrientes G y H, corresponden a las líneas de inyección de vapor al cabezal del pozo y a la purga o venteo de vapor, respectivamente. En esta fase se realizan remezclas controladas del condensado, por lo que no hay pérdida de condensado ni efluente generado, y la masa total va a la salida del sistema. Importante resaltar que durante todo el proceso no se generan sólidos extras ni incrustaciones.

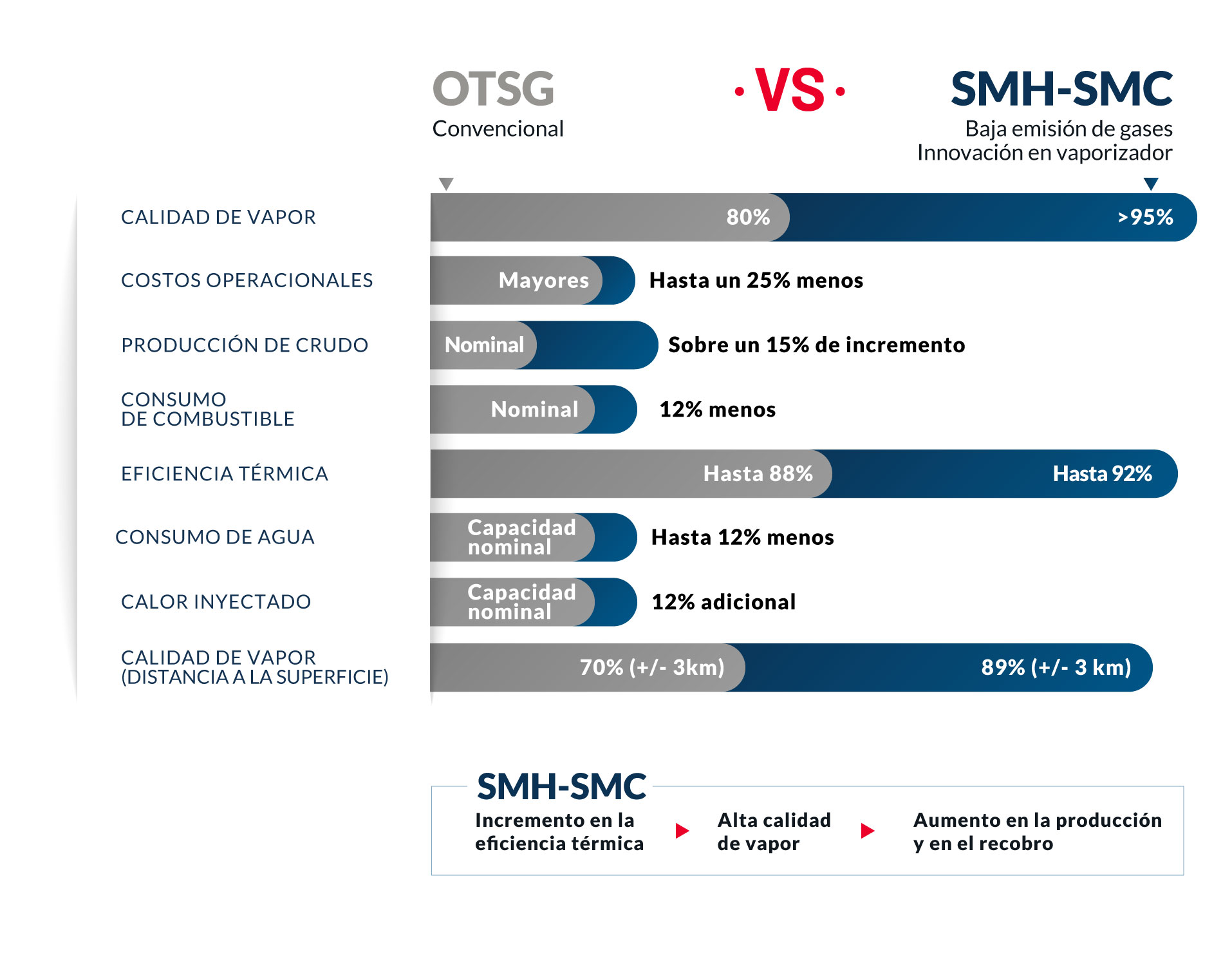

VENTAJAS DEL SMH Y SMC VS. OTSG CONVENCIONAL

SERVICIO DE SOPORTE Y ACOMPAÑAMIENTO EN CADA PASO

Nakasawa se asegura de que los proyectos de sus clientes sean exitosos, creando una alianza técnica que comienza desde el diseño estratégico del proyecto hasta su implementación, mantenimiento y monitoreo.

Nakasawa brinda un servicio de implementación absoluta del proyecto, que incluye los recursos humanos y los consumibles necesarios para asegurar una exitosa recuperación mejorada del petróleo en pozos de crudo pesado nuevos y maduros. A su vez, los clientes pueden contar con capacitaciones para su personal sobre el uso óptimo del SMH o SMC para que, a medida que se logren sus objetivos, puedan manejar la tecnología por sí solos y sin complicación alguna.

NAKASAWA

A TU LADO

El servicio completo de Nakasawa para implementar sus tecnologías de inyección de vapor incluye:

- Análisis de los yacimientos.

- Servicios y operación de los generadores de vapor y todos los equipos, y servicios auxiliares.

- Sistemas de completación y equipos para pozos de inyección.

- Sistema de completación y equipos para pozos productores.

- Monitoreo de las variables del yacimiento, optimización y producción.

DIRECTRICES Y REGULACIONES

El servicio de inyección de vapor cumplirá en todo momento con las regulaciones nacionales e internacionales aplicables, y se prestará teniendo en cuenta las recomendaciones de los fabricantes de los equipos en cuanto a la instalación, cableado, calibración, pruebas, requisitos especiales, y demás, para el correcto funcionamiento y operación de los equipos. Entre las regulaciones de las cuales se rige el servicio, se encuentran:

- ISA (La Sociedad de Instrumentación, Sistemas y

Automatización) - IEC (Comisiones Electrotécnicas Internacionales)

- ANSI (El Instituto Nacional Estadounidense de Estándares)

- A.P.I. (Instituto Americano del Petróleo)

- ASME (Sociedad Americana de Ingenieros Mecánicos)

- NEMA (Asociación Nacional de Fabricantes Eléctricos)

- NFPA (Asociación Nacional de Protección contra el Fuego)

- ASTM (Sociedad Americana para Pruebas y Materiales)

- ISO (Organización Internacional de Normalización)