El control y monitoreo diario de parámetros se realiza a través de los sistemas de Supervisión, Control y Adquisición de Datos (SCADA), radio y/o fibra óptica que permiten la ejecución de acciones en tiempo real y la medición automática de parámetros operacionales y condiciones de superficie y fondo, entre ellos:

• Temperatura.

• Presión.

• Tasa de inyección.

• Tasa de producción de crudo, gas, agua.

• Predicción del comportamiento de producción.

CONTROL Y MONITOREO DIARIO DE PARÁMETROS

AUTOMATIZACIÓN

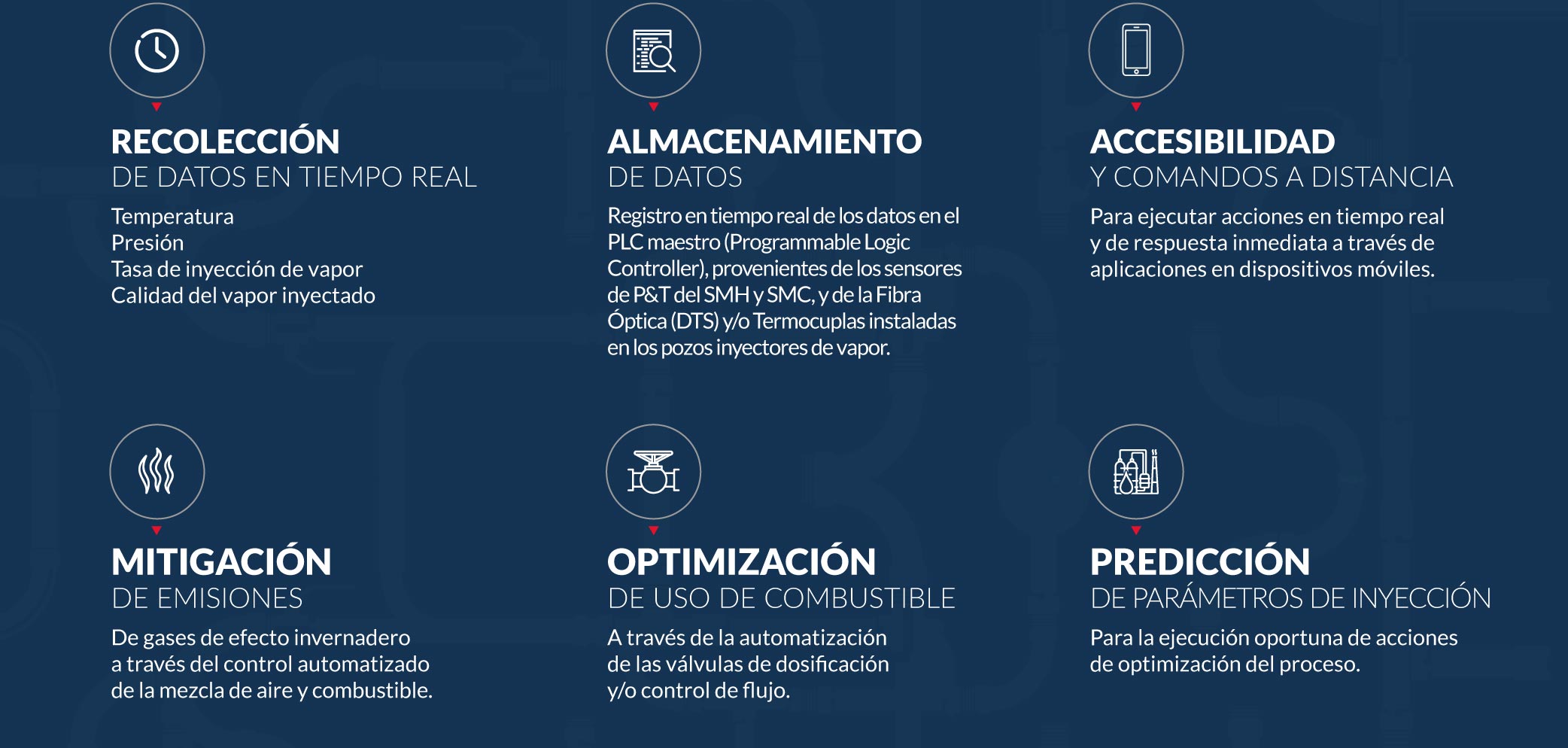

Nakasawa ha incorporado como parte integral del proceso, el monitoreo de los parámetros de operación durante las etapas de inyección y post- inyección para llevar un control exhaustivo de las operaciones.

Para garantizar un óptimo desempeño de los equipos y la obtención de alta eficiencia del proceso la empresa ha incorporado la instalación de sensores de alta tecnología para la medición de los parámetros de fondo de pozo y superficie.

Los sensores registran datos sobre parámetros como presión y temperatura, fibra óptica (DTS) y termocuplas para verificar el estado progresivo del sistema de medición, registrando los indicadores de eficiencia del sistema, así como los dígitos de amplitud y la fase. Además de documentar el rendimiento del sensor a lo largo del tiempo, también se pueden detectar posibles problemas con anticipación.

Por medio del proceso de automatización es posible generar gráficos, segundo a segundo, de tendencia de presión y temperatura para agilizar la toma de acciones y la optimización de la producción en tiempo real.

Toda la data es recopilada e integrada en un PLC de última generación y vinculada a una base de datos central, y son accesibles a través de una aplicación que permite al usuario visualizar en tiempo real en todos los dispositivos móviles, el estatus actual del proceso de generación e inyección de vapor.

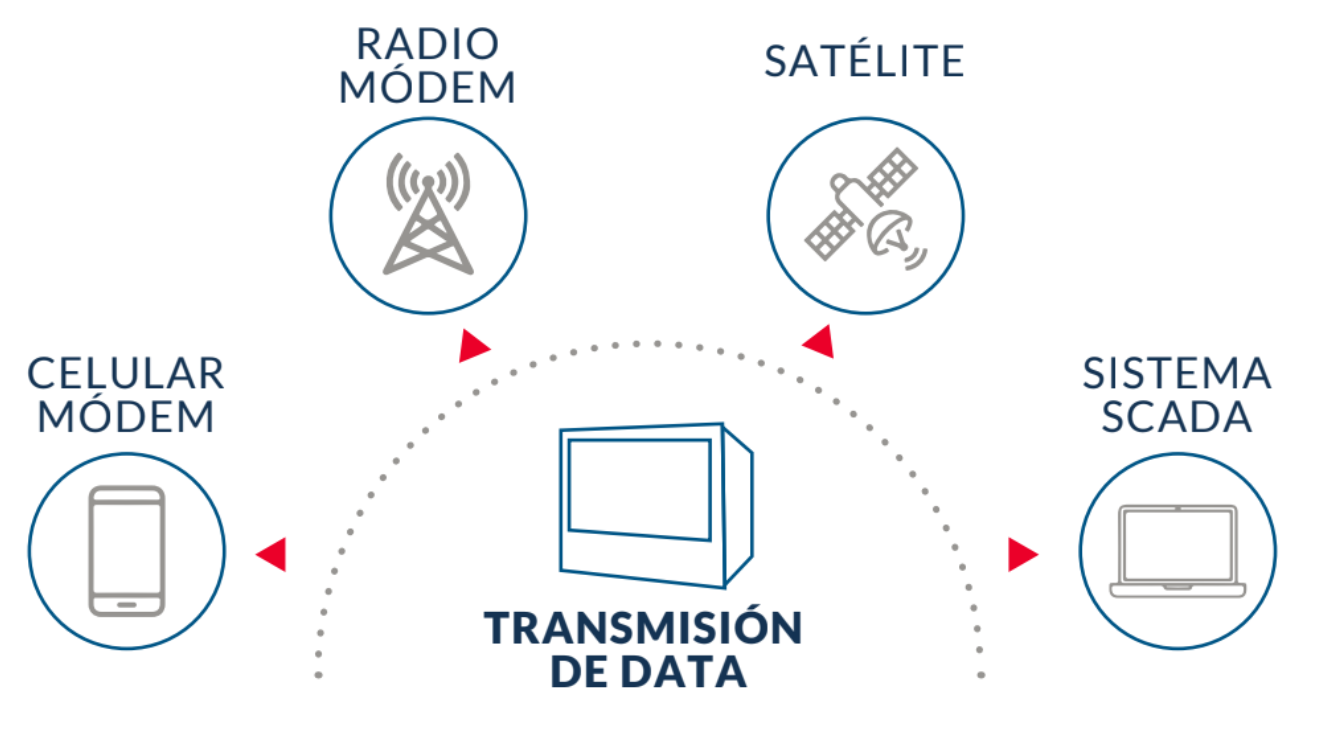

La transmisión de datos puede ser ejecutada a través de tecnología satelital de forma directa mediante lazos de control con los sensores de medición, y haciendo uso de un software y/o aplicación para la visualización vía remota. Además, se puede adecuar la arquitectura de transmisión de datos a través de los siguientes medios:

- Sistema Scada

- Fibra Óptica

- Señal de Radio

- Frecuencia GSM (Celular / Modem)

Además de la disponibilidad de data, el Super Matroid Heater y Super Matroid Cyclone cuentan con un sistema de predicción de las tendencias de los parámetros de inyección de vapor a través de algoritmos matemáticos para la ejecución de acciones de optimización.